Some refer to through-spindle coolant as “coolant through the spindle” or simply CTS.Whatever you call it, CTS works just as its name implies.

Some refer to through-spindle coolant as “coolant through the spindle” or simply CTS.Whatever you call it, CTS works just as its name implies.

The machine builder installs a rotary union at the top of the spindle, some plumbing and hoses, and voila, so that your cutting tools would be cooled and well-lubricated. 😉

Why do you need CTS system?

When the machine is processed, high-temperature water vapor will be generated, and the water vapor on the surface of the workpiece will isolate the adhesion of cutting fluid, resulting in a very low effect of cooling the workpiece or tool.

If you would like to make sure machine and tools’ durability, try to adopt CTS system.Below we will know what CTS is and why we need it in machining process.

What is spindle through coolant?

CTS is used in areas where it is necessary to control the temperature, humidity and filtration. The range was developed in accordance with quality standard and with certified mechanical properties, in search of lower energy consumption to respect the environment.

By forcing coolant through the tip of the rotary tool, spindle through coolant (CTS) can prevent damage to workpieces, reduce cycle time, and extend the life of your tool. Depending on the application, coolant can be water-based, petroleum-based, or an emulsion of oil and water.

What is the advantage of CTS system ?

CTS improves tool life, allows both deep hole drilling and blind pocket milling. It also allows high speeds and reduces cycle time.

What is the bar value of CTS meaning?

From 6 , 20 ,30 ,50 to 70 bars.

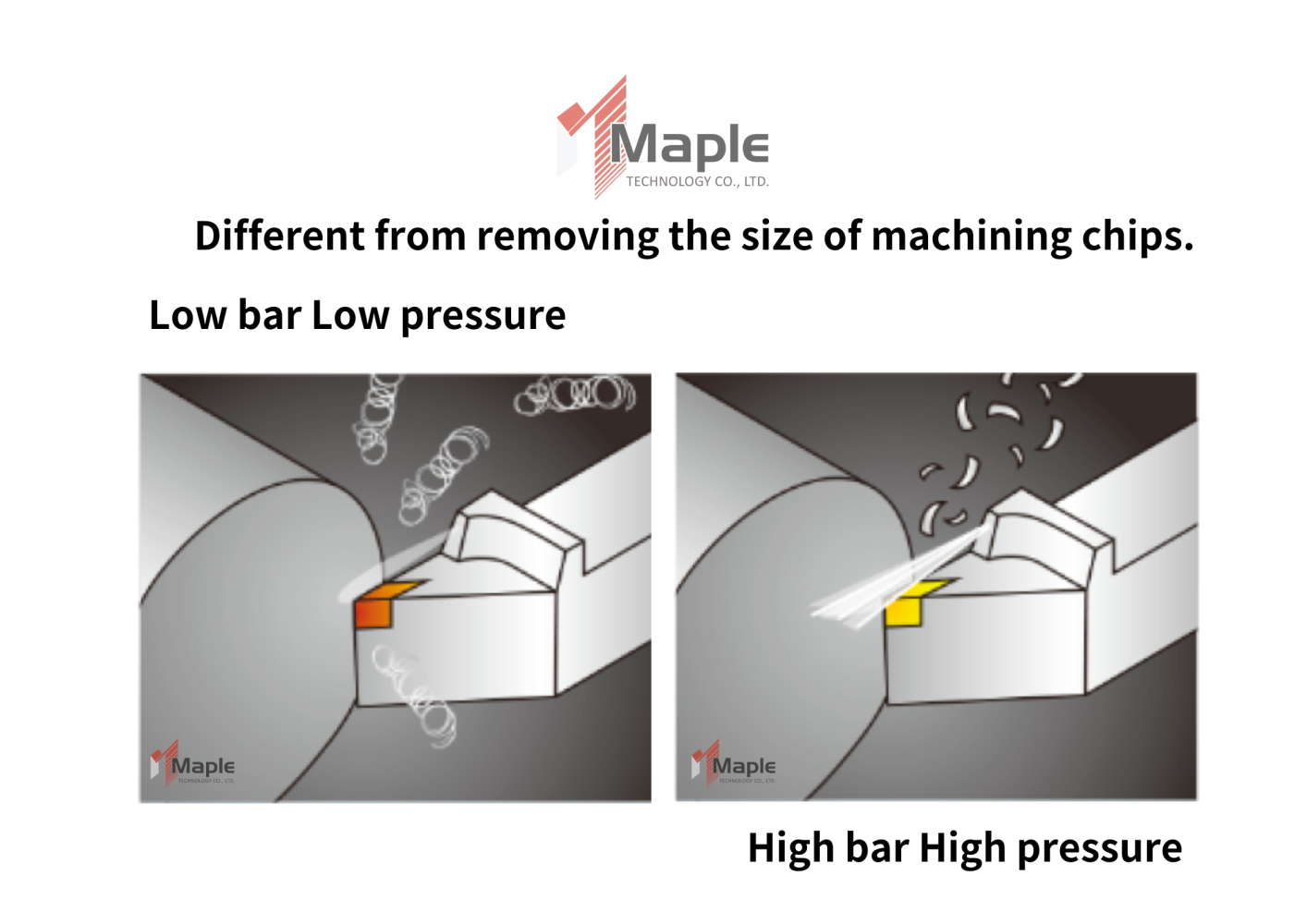

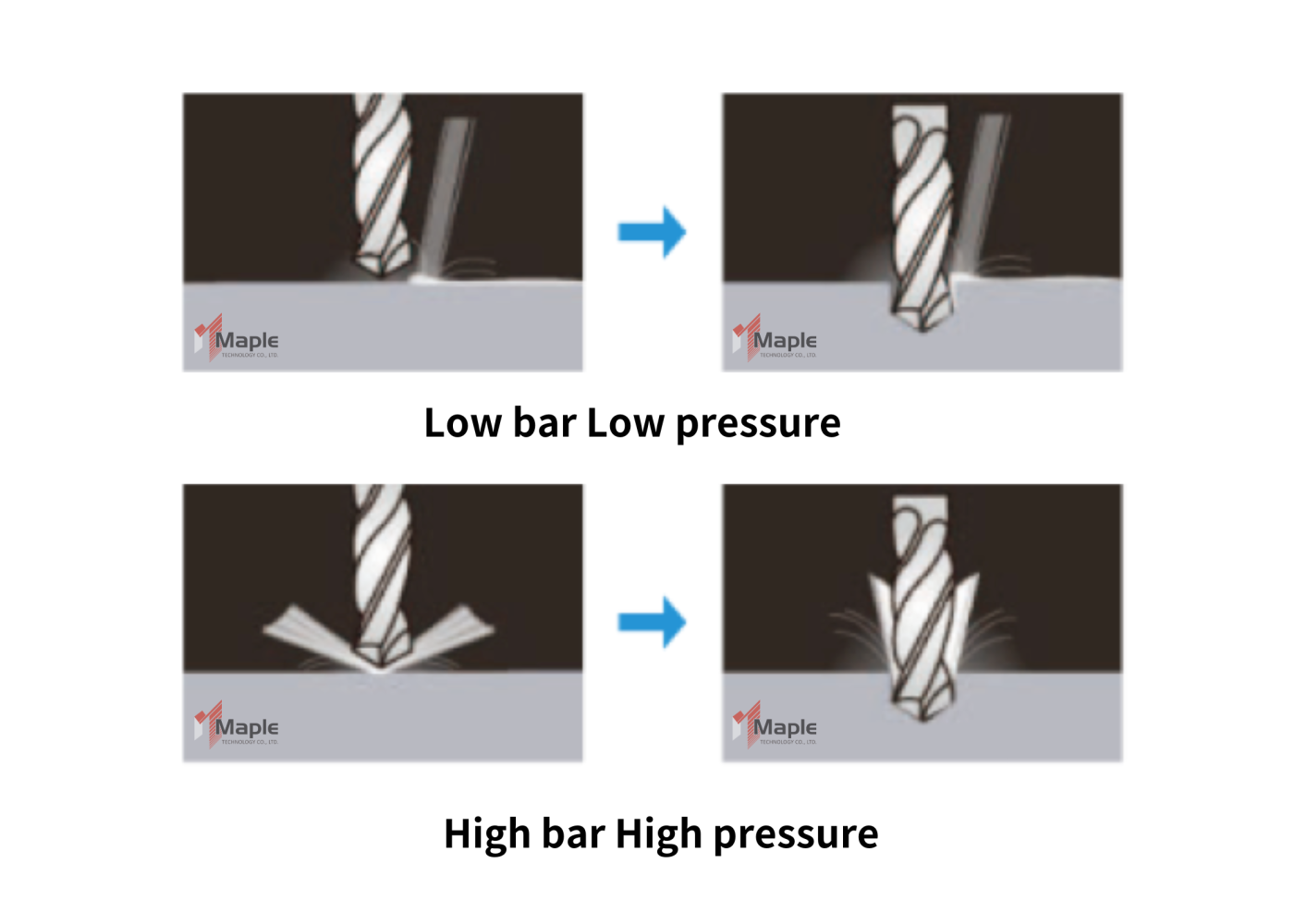

The higher the number of bars, the greater the pressure.

You could choose CTS system according to the size of processed iron filings and material.

What brand does Maple-Tech adopt?

CHUANG FONG CO., LTD.

During low-pressure machining, it is necessary to return the knife from time to time, and the cutting water can remove the iron filings in the hole. The processing process is more time-consuming.

In high-pressure machining, there is no need to return the knife. The cutting water can directly hit the processing point and remove the iron filings directly, which can improve the processing efficiency.